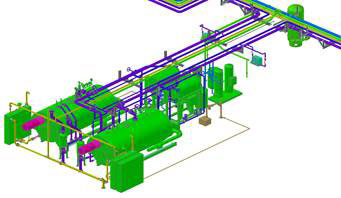

Piping / Mechanical Capabilities

Zentech’s personnel has experience with:

- Chemical processes which produced polymers for the plastics industry.

Air separation, liquefaction, storage, transfer and expansion systems for gasses such as Nitrogen, Hydrogen, Oxygen as well as Helium and Argon processing.

- Petrochemical refining, Sulfur recovery units and Olefin separation.

- Aerospace fluid transfer systems for storage, expansion, and compression of cryogenic Fluids (including Oxygen and LOX system).

- High temperature ceramic piping for high temperature supersonic fluid transfer and testing

- Ethylene, Methane, Silane, and JP fluids, for storage, transfer and delivery of high temperature fluids in excess of 3500 deg F for Mach 4 thru 7 simulation and testing for the High Temperature 8 Foot Test Tunnel Facility.

Zentech Engineering Work:

- Zentech mechanical engineering staff has experience working with piping systems ranging from:

- Pressures from Full vacuum to 15,000 psi [1035 BAR] (liquid and gas)

- Temperatures from -60oF [-51oC] to 1000oF [538oC]

- Zentech has designed systems including but not limited to:

- Potable water, sewage and breathing air all requiring health considerations along with fluid dynamics.

- Drilling and completion fluids involving chemical compounds such as Corrosion inhibitors, Zinc Bromide and Hydrogen Sulfide

- Gas systems such as Nitrogen, Oxygen and Methane

- Liquid natural gas, liquid Nitrogen, and Fluorocarbon Cryogenic systems